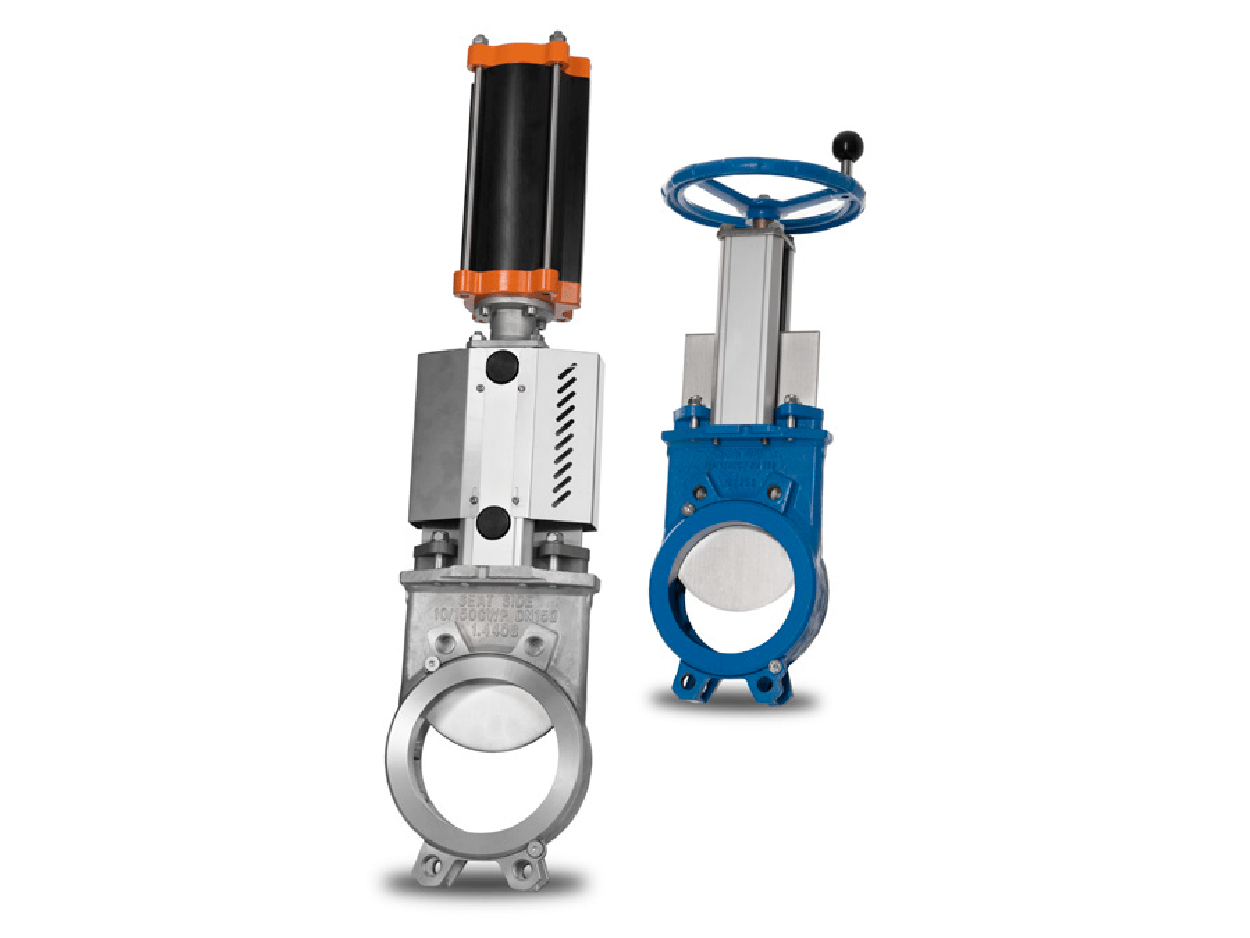

KNIFE GATE VALVE MV

Stafsjö’s knife gate valve MV can be used within a wide range of applications on both dry and wet media such as pulp stock up to 7% concentrations, sludge, slurry, biomass, water, ash, granulate and different kinds of waste.

The MV valve is modular designed and it can easily be customized in materials, with actuators and related automation accessories to different process conditions. As standard it is available in a stainless steel version and one in nodular iron, but it can also be supplied in a range of high alloy materials such as Duplex and 254 SMO. Stafsjö’s retainer ring system offers great flexibility and several seat material options. Up to DN 800 the MV holds a one piece valve body and from DN 900 it features a rigid two piece version.

Stafsjö’s gland box system with TwinPack braids ensures that no media reaches the surrounding environment. It can also be reinforced with a box bottom scraper or with a double gland for the most demanding applications.

The MV valve is available in size ranging from DN 50 up to DN 1600 (2” to 64”).

Full Product Range – Technical Information

Main Dimensions

| DN | A | B | C | D | E | F | G | H | I1) | J | K | L | M2) | N3) | W4) |

| 50 | 52 | 41 | 91 | 80 | 200 | 56 | 360 | 529 | SC100 | 116 | 630 | 230 | SA07.2 | F10 A | 7 |

| 65 | 64 | 41 | 107 | 80 | 200 | 65 | 380 | 549 | SC100 | 130 | 650 | 250 | SA07.2 | F10 A | 7 |

| 80 | 79 | 51 | 124 | 80 | 200 | 88 | 405 | 574 | SC100 | 135 | 675 | 275 | SA07.2 | F10 A | 8 |

| 100 | 103 | 51 | 154 | 80 | 200 | 102 | 453 | 622 | SC100 | 155 | 723 | 323 | SA07.2 | F10 A | 10 |

| 125 | 128 | 56 | 179 | 80 | 250 | 116 | 495 | 714 | SC100 | 178 | 765 | 365 | SA07.2 | F10 A | 13 |

| 150 | 153 | 60 | 204 | 80 | 250 | 130 | 550 | 769 | SC100 | 205 | 820 | 420 | SA07.2 | F10 A | 15 |

| 200 | 202 | 60 | 267 | 145 | 315 | 160 | 694 | 1009 | SC160 | 268 | 1115 | 555 | SA07.6 | F10 A | 31 |

| 250 | 250 | 69 | 320 | 145 | 315 | 192 | 779 | 1199 | SC160 | 320 | 1250 | 640 | SA07.6 | F10 A | 40 |

| 300 | 302 | 78 | 374 | 145 | 315 | 230 | 879 | 1299 | SC160 | 375 | 1400 | 740 | SA10.2 | F10 A | 55 |

| 350 | 332 | 78 | 419 | 175 | 400 | 210 | 993 | 1562 | SC200 | 420 | 1550 | 820 | SA10.2 | F10 A | 90 |

| 400 | 380 | 89 | 479 | 175 | 400 | 245 | 1083 | 1652 | SC200 | 490 | 1690 | 910 | SA10.2 | F10 A | 120 |

| 450 | 428 | 89 | 535 | 200 | 520 | 280 | 1180 | 1752 | SC200 | 560 | 1820 | 990 | SA10.2 | F10 A | 180 |

| 500 | 470 | 114 | 580 | 250 | 520 | 315 | 1333 | 2007 | SC200 | 625 | 2028 | 1145 | SA10.2 | F10 A | 245 |

| 600 | 560 | 114 | 680 | 260 | 635 | 370 | 1558 | 2360 | SC250 | 740 | 2358 | 1370 | SA10.2 | F10 A | 340 |

| 700 | 665 | 118 | 800 | 310 | 635 | 400 | 1750 | 2717 | SC250 | 865 | 2650 | 1565 | SA14.2 | F14 A | 460 |

| 750 | 710 | 118 | 860 | 305 | 635 | 430 | 1880 | 2791 | SC320 | 930 | 2787 | 1635 | SA14.2 | F14 A | 510 |

| 800 | 760 | 118 | 900 | 310 | 635 | 450 | 1970 | 2943 | SC320 | 985 | 2970 | 1780 | SA14.2 | F14 A | 600 |

| 900 | 855 | 118 | 1010 | 320 | 635 | 580 | 2220 | 3148 | SC320 | 1160 | 3340 | 1985 | SA14.6 | F14 A | 900 |

| 1000 | 950 | 150 | 1110 | 320 | 635 | 640 | 2400 | 3608 | SC320 | 1280 | 3630 | 2215 | SA14.6 | F14 A | 1500 |

| 1200 | 1200 | 150 | 1335 | 490 | – | 750 | – | – | – | 1500 | 4300 | 2860 | SA16.2 | F16 A | 2160 |

| 1300 | 1300 | 147 | 1442 | 596 | – | 813 | – | – | – | 1626 | 4737 | 3020 | SA16.2 | F16 A | 3300 |

| 1400 | 1422 | 180 | 1574 | 510 | – | 863 | – | – | – | 1726 | 4950 | 3224 | SA16.2 | F16 A | 3300 |

| 1600 | 1560 | 190 | 1755 | 550 | – | 950 | – | – | – | 1900 | 5365 | 3453 | SA16.2 | F16 A | 5000 |